What Is a Bellows Type Steel Globe Valve?

What Is a Bellows Type Steel Globe Valve?

-

Definition

A Bellows Type Steel Globe Valve is a globe valve designed with a bellows seal structure instead of a conventional packing seal. This design ensures complete leak prevention, especially in systems operating under high pressure, high temperature, or containing hazardous liquids and steam.

-

Structure of a Bellows Type Globe Valve

-

Body: Made from carbon steel, alloy steel, or stainless steel, capable of withstanding high temperature and pressure.

-

Bonnet: Houses the bellows seal mechanism.

-

Bellows Seal: Made from stainless steel (SS304, SS316L), capable of expanding and contracting to ensure absolute sealing.

-

Stem: Connects the valve disc and controls the opening/closing of the flow.

-

Disc: Regulates the flow of liquid or steam in the system.

-

Handwheel: Used to manually open or close the valve.

-

Advantages of Bellows Type Globe Valves

-

Absolute Leak Prevention: The bellows seal design completely prevents medium leakage to the outside.

-

Long Service Life: The bellows are designed to withstand thousands of open/close cycles, extending valve life.

-

High Temperature and Pressure Resistance: Suitable for steam, hot oil, compressed air, and chemical systems.

-

Reduced Maintenance Costs: No need for frequent replacement of packing seals like conventional globe valves.

-

Compliance with Safety Standards: Especially important in industries requiring high sealing performance, such as chemicals, pharmaceuticals, and oil & gas.

-

Applications of Bellows Type Globe Valves

-

Steam Systems: Power plants, industrial boilers.

-

Oil & Gas and Chemical Industries: Piping systems carrying hazardous and toxic media.

-

Pharmaceutical and Food Industries: Saturated steam systems, purified water systems.

-

Central Heating and HVAC Systems: Controlling the flow of hot water or thermal oil.

-

Common Standards and Notable Manufacturers

-

Design Standards: API 602, ANSI B16.34, DIN, JIS.

-

Popular Brands: KSB (Germany), ETM (China).

-

Product Availability: Available in stock. Please contact us for a quotation.

Technical Specifications of ETM Bellows Seal Steel Globe Valve Flanged DIN PN16

-

MODEL: P.061

-

Medium: Steam, Hot Oil

-

Body: GS-C25 Steel

-

Disc: A105 Cr13

-

Bellows: SS316L

-

Maximum Working Temperature: 400°C

-

Maximum Working Pressure: 16 bar (PN16)

-

Flange Connection: DIN PN16

Bellows Type Globe Valves are an optimal solution for systems requiring high sealing performance, reducing leakage, and improving operational efficiency in harsh industrial environments.

Contact Information:

PHUC MINH ENGINEERING CO., LTD.

Address: 92/38, Street No. 12, Quater 18, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City, Vietnam

CellPhone/Zalo: +84907450506 / +84902720814 / +84902800728

Tel: +84 28 3535 2125

Fax: +84 28 3535 0254

Email: info@pm-e.vn

Website: pm-e.vn

Related News

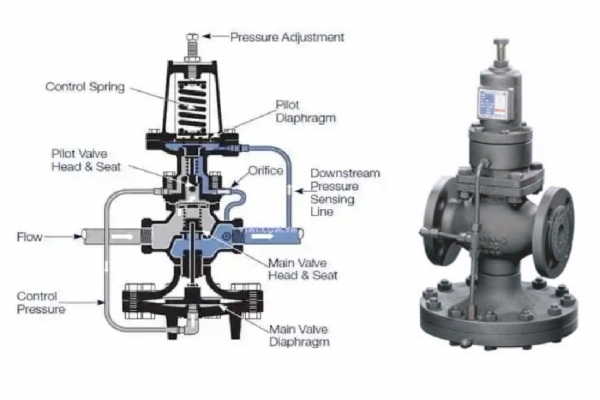

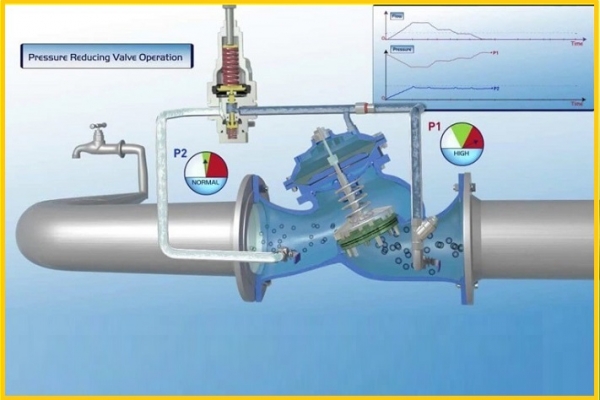

What Is a Steam Pressure Reducing Valve?

05/02/2025

A Steam Pressure Reducing Valve (PRV) is a device used in steam systems to reduce steam pressure from a high level to a stable, controlled level as required by the application. It helps regulate pipeline pressure, ensures equipment safety, and optimizes system efficiency. Applications of Steam Pressure Reducing Valves Steam PRVs are widely used across various industries such as: Power Plants: Controlling steam pressure supplied to turbines. Textile Industry: Providing suitable steam pressure for steamers and ironing machines. Food & Beverage Industry: Applied in cooking and steaming processes. Oil & Gas, Chemical Industry: Used in heating and chemical processing systems.

DIDTEK Steel Valves for Oil & Gas and General Industrial

25/11/2024

DIDTEK Valve Group, established in 1985, is one of China’s leading industrial valve manufacturers. The company is headquartered in Lin Yang Industrial Zone, Oubei Town, Yongjia County, Zhejiang Province. DIDTEK specializes in the design, production, and export of high-quality industrial valves, serving industries such as oil & gas, petrochemicals, power generation, marine, water treatment, and more. Main Products Gate Valves Globe Valves Ball Valves (Floating Ball Valves, Trunnion Mounted Ball Valves) Butterfly Valves Check Valves Knife Gate Valves Safety Valves Valves for high temperature, high pressure, and cryogenic applications

Types of Mechanical Valves in the Industrial Valve Industry: Advantages, Disadvantages, and Their Applications

15/10/2024

The industrial valve industry plays an important role in piping systems, helping to control and regulate the flow of liquids, gases, and steam. Below is an article about the common types of mechanical valves in the industrial valve industry: gate valves, globe valves, ball valves, butterfly valves, check valves, Y-strainers, needle valves, angle valves, diaphragm valves, and sanitary valves. We will analyze the advantages, disadvantages, and applications of each type of valve.

10 Most Important Industrial Equipment in Factories

15/10/2024

Modern industrial factories rely on a range of equipment to maintain high performance and ensure continuous operation. Below is a detailed description of the 10 most important types of industrial equipment, including their functions, applications, advantages, and disadvantages.

Operating Principle Of Samyang Korea Pressure Reducing Valve

15/10/2024

At the initial position, the valve is fully open, the width of the outlet is set by the adjusting screw. The effect of the valve almost keeps the output pressure value constant. In case the output pressure value increases in the hydraulic system; the pressure of the cavity connected to the valve outlet by the connecting groove also increases; pushing the control piston up reduces the cross-section of the outlet; leading to a decrease in the output pressure. When the output pressure decreases, the control piston goes down, increasing the cross-section of the outlet; leading to an increase in the output pressure.

.png)