What Is a Bellows Type Steel Globe Valve?

What Is a Bellows Type Steel Globe Valve?

-

Definition

A Bellows Type Steel Globe Valve is a globe valve designed with a bellows seal structure instead of a conventional packing seal. This design ensures complete leak prevention, especially in systems operating under high pressure, high temperature, or containing hazardous liquids and steam.

-

Structure of a Bellows Type Globe Valve

-

Body: Made from carbon steel, alloy steel, or stainless steel, capable of withstanding high temperature and pressure.

-

Bonnet: Houses the bellows seal mechanism.

-

Bellows Seal: Made from stainless steel (SS304, SS316L), capable of expanding and contracting to ensure absolute sealing.

-

Stem: Connects the valve disc and controls the opening/closing of the flow.

-

Disc: Regulates the flow of liquid or steam in the system.

-

Handwheel: Used to manually open or close the valve.

-

Advantages of Bellows Type Globe Valves

-

Absolute Leak Prevention: The bellows seal design completely prevents medium leakage to the outside.

-

Long Service Life: The bellows are designed to withstand thousands of open/close cycles, extending valve life.

-

High Temperature and Pressure Resistance: Suitable for steam, hot oil, compressed air, and chemical systems.

-

Reduced Maintenance Costs: No need for frequent replacement of packing seals like conventional globe valves.

-

Compliance with Safety Standards: Especially important in industries requiring high sealing performance, such as chemicals, pharmaceuticals, and oil & gas.

-

Applications of Bellows Type Globe Valves

-

Steam Systems: Power plants, industrial boilers.

-

Oil & Gas and Chemical Industries: Piping systems carrying hazardous and toxic media.

-

Pharmaceutical and Food Industries: Saturated steam systems, purified water systems.

-

Central Heating and HVAC Systems: Controlling the flow of hot water or thermal oil.

-

Common Standards and Notable Manufacturers

-

Design Standards: API 602, ANSI B16.34, DIN, JIS.

-

Popular Brands: KSB (Germany), ETM (China).

-

Product Availability: Available in stock. Please contact us for a quotation.

Technical Specifications of ETM Bellows Seal Steel Globe Valve Flanged DIN PN16

-

MODEL: P.061

-

Medium: Steam, Hot Oil

-

Body: GS-C25 Steel

-

Disc: A105 Cr13

-

Bellows: SS316L

-

Maximum Working Temperature: 400°C

-

Maximum Working Pressure: 16 bar (PN16)

-

Flange Connection: DIN PN16

Bellows Type Globe Valves are an optimal solution for systems requiring high sealing performance, reducing leakage, and improving operational efficiency in harsh industrial environments.

Contact Information:

PHUC MINH ENGINEERING CO., LTD.

Address: 92/38, Street No. 12, Quater 18, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City, Vietnam

CellPhone/Zalo: +84907450506 / +84902720814 / +84902800728

Tel: +84 28 3535 2125

Fax: +84 28 3535 0254

Email: info@pm-e.vn

Website: pm-e.vn

Related News

FDA-Approved Rubber Gaskets – Safe Solutions for Food & Medical Applications

23/04/2025

FDA-Approved Rubber Gaskets – Safe Solutions for Food & Medical Applications Phuc Minh Engineering Co., Ltd. is proud to be one of the leading distributors in Vietnam of rubber gaskets for food and medical applications. Our products are made from high-quality materials and meet the strict FDA (U.S. Food and Drug Administration) standards – ensuring safety for direct contact with food and medical equipment.

HIGH-TEMPERATURE GASKETS – UP TO 1000°C WITH THERMa-PUR™ 4122 MATERIAL

23/04/2025

HIGH-TEMPERATURE GASKETS – UP TO 1000°C WITH THERMa-PUR™ 4122 MATERIAL In many heavy industries such as chemical processing, oil refining, cement, and power generation, sealing materials must endure extreme temperatures, high pressure, and harsh oxidative environments. Phuc Minh Engineering Co., Ltd. is proud to be a distributor of high-temperature gaskets rated up to 1000°C, combining Garlock’s advanced THERMa-PUR™ 4122 material with Corrugated Metal Gaskets (CMG) – delivering an optimal sealing solution for extreme industrial conditions.

Trusted Industrial Valve Distributor – Industry Leader

26/02/2025

With the continuous growth of Vietnam's economy, the demand for industrial valves and related technical solutions has significantly increased. In this article, we would like to introduce a reputable and leading industrial valve distributor in this field — Phuc Minh Engineering Co., Ltd.

Top 10 best water flow meter brands today

12/02/2025

Sensus water flow meter: Origin: Germany. Advantages: The product has high precision, durable design and stable operation in many different environmental conditions. Sensus clocks are certified by European CO, CQ, suitable for large-scale projects.

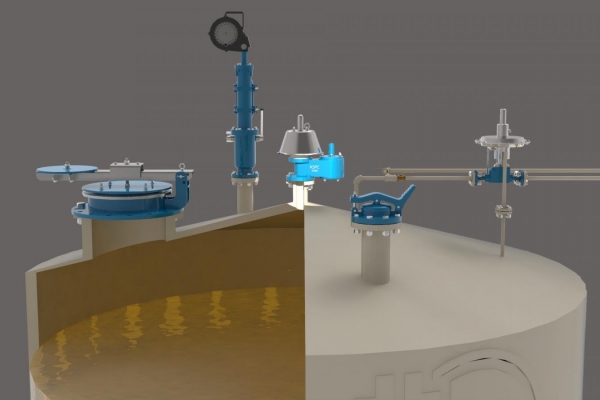

What Is a Breather Valve?

05/02/2025

A breather valve, also known as a pressure-vacuum relief valve (PVRV), is a safety device that protects storage tanks from explosion or collapse caused by pressure differences. It is typically installed on top of storage tanks for fuels, chemicals, LPG, or gases.

.png)