PTFE (Polytetrafluoroethylene)

PTFE (Polytetrafluoroethylene)

Products

-

We have the largest stock of PTFE stock shapes in Singapore, both in Virgin, Filled, Etched or Reprocessed materials.

-

PTFE is used when conditions of operation require:-

High operating temperature (continuous 270°C), excellent chemical resistance, or low coefficient of friction. -

It has good electrical insulation and thermal expansion rates.

-

Non-toxic food grade and chemically inert.

-

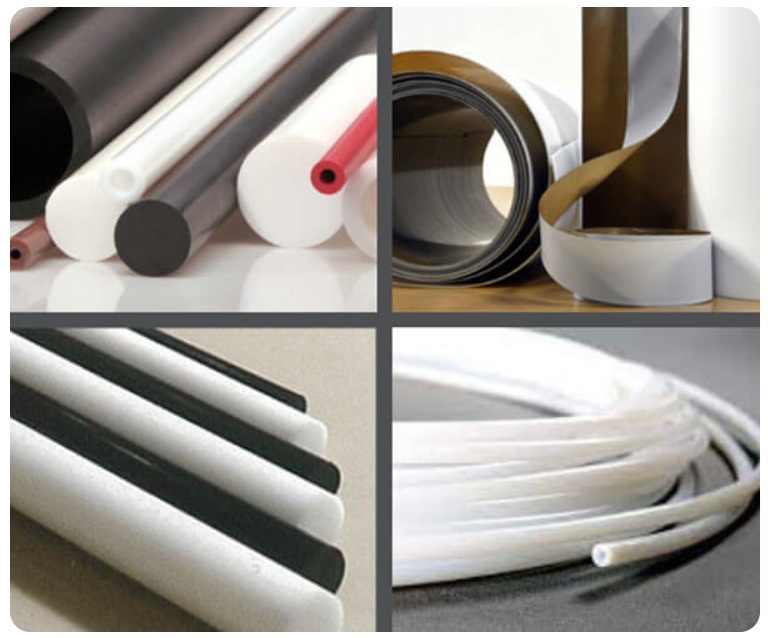

The following types of PTFE Products are available:-

-

Virgin & Reprocessed PTFE

-

Filled or compounded PTFE

-

Etched PTFE Sheets

-

Expanded PTFE sheets

-

Join Sealant & Lock Cords

-

Flexible & Rigid Tubes

-

Related News

Industrial Valves for Chemical Plants, Oil Refineries, and Petroleum | Phuc Minh

17/09/2025

Phuc Minh Engineering – Trusted supplier of industrial valves for chemical plants, oil refineries, and petroleum systems. Genuine products with CO-CQ, competitive prices.

Applications of Industrial Valves in Steam and Boiler Systems

17/09/2025

The role of industrial valves in steam and boiler systems In factories using steam and boiler systems, safety control and energy efficiency are critical. Industrial valves play a vital role in:

Industrial Valves – Effective Flow Control Solutions | Phuc Minh Engineering Co., Ltd.

17/09/2025

What is an industrial valve? Industrial valves are essential mechanical devices in piping systems, responsible for regulating, opening/closing, and controlling the flow and pressure of liquids, gases, or steam. They are widely applied in many industries:

Composite Hose – Leading Anti-Corrosion, Chemical-Resistant Flexible Hose Solution in Vietnam

11/08/2025

High-quality imported composite hose, resistant to corrosion, chemicals, oils, and solvents. Available in Vietnam at competitive prices, full size range, and fast delivery.

Comprehensive Valve and Process Control Solutions for Key Industries

16/07/2025

Water Treatment Industry – Scale and Challenges Water treatment is a vital sector, ensuring safe water supply for both residential and industrial use. As urbanization and industrialization accelerate, water treatment systems must meet increasingly stringent requirements: Ensure output water quality meets national and international standards. Maintain continuous, stable operation while minimizing unexpected downtime. Optimize energy efficiency and reduce operational and maintenance costs. Integrate monitoring and automation for enhanced remote control and management. Comply with strict environmental protection regulations and carbon emission reduction goals.

.png)