Composite Hose – Leading Anti-Corrosion, Chemical-Resistant Flexible Hose Solution in Vietnam

Composite Hose – Optimal Solution for Industrial Applications in Vietnam

A composite hose is a flexible hose made from multiple layers of composite materials, combining plastics, reinforcement fibers, and chemical-resistant membranes. With its unique structure, the hose offers outstanding corrosion resistance and can handle a wide range of solvents, acids, alkalis, and petroleum products. It is the top choice for chemical, oil & gas, marine, and food industries in Vietnam.

Structure and Features of Composite Hose

-

Multi-layer construction:

-

Inner layer: special plastic materials (Polypropylene, PTFE, or Nylon) for chemical resistance.

-

Reinforcement layer: fiberglass or synthetic fibers for strength.

-

Outer layer: PVC, PU, or synthetic rubber for UV and abrasion protection.

-

-

Key features:

-

Superior corrosion resistance and long lifespan.

-

High pressure and temperature resistance (typically -40°C to +100°C).

-

Lightweight, easy to install and move.

-

Compatible with a wide range of chemicals, solvents, and fuels.

-

Applications of Composite Hose in Vietnam

-

Chemical industry: transporting acids, alkalis, and organic solvents.

-

Oil & gas: transferring gasoline, diesel, jet fuel.

-

Marine industry: loading/unloading fuel on ships and ports.

-

Food industry: transferring edible oils, alcohol, syrups, and food-safe liquids.

-

Environmental sector: handling liquid waste and industrial wastewater.

Advantages of Composite Hose Over Metal and Rubber Hoses

-

Better corrosion resistance – does not rust like metal pipes.

-

Lighter weight – reduces transport and installation costs.

-

Flexible – easy to bend and fit into tight spaces.

-

Versatile applications – from heavy industry to food-grade uses.

Standards and Specifications of Composite Hose

-

Common sizes: DN25, DN50, DN80, DN100, DN150…

-

Working pressure: 10–20 bar.

-

International standards: BS EN 13765, BS EN 13766.

-

Fittings: Camlock, Flange, Threaded, Quick Coupling.

Trusted Composite Hose Supplier in Vietnam

We specialize in importing and distributing composite hoses from top global brands such as Dantec (UK), Novaflex (USA), Trelleborg (France)…

-

Ready stock, various sizes, and standards.

-

Fast quotation and on-site technical support.

-

Genuine warranty with full CO/CQ certification.

👉 Contact Phuc Minh Engineering Co., Ltd today to get the best price for composite hoses tailored to your needs.

-

Hotline: 0902720814 - 0907460506 - 0902800728

-

Tel: 028-3535.2125 - Fax: 028.3535.0254

-

Website: www.pm-e.vn

-

Email: info@pm-e.vn

Commitment: Genuine products – Best prices – Nationwide delivery – Free technical support.

Benefits of Buying from Us

-

Free technical consultation.

-

Nationwide delivery.

-

Competitive pricing.

-

Dedicated after-sales service.

Related News

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

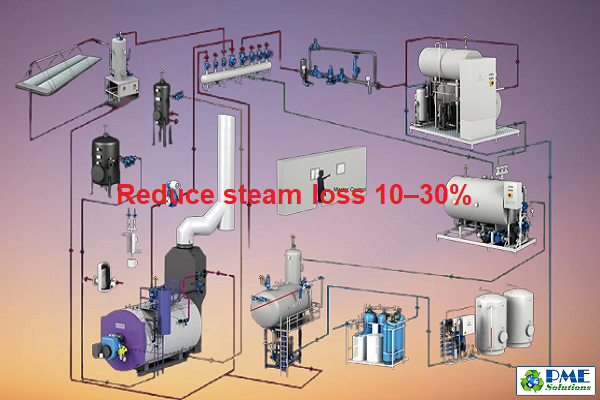

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

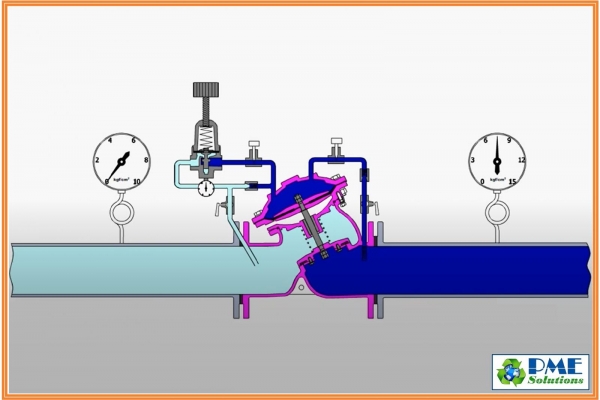

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

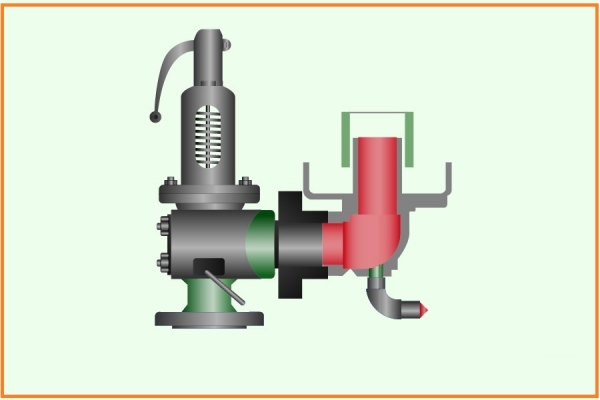

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

.png)