Benefits, Functions, and Applications of Pressure Reducing Valves

Benefits, Functions, and Applications of Pressure Reducing Valves

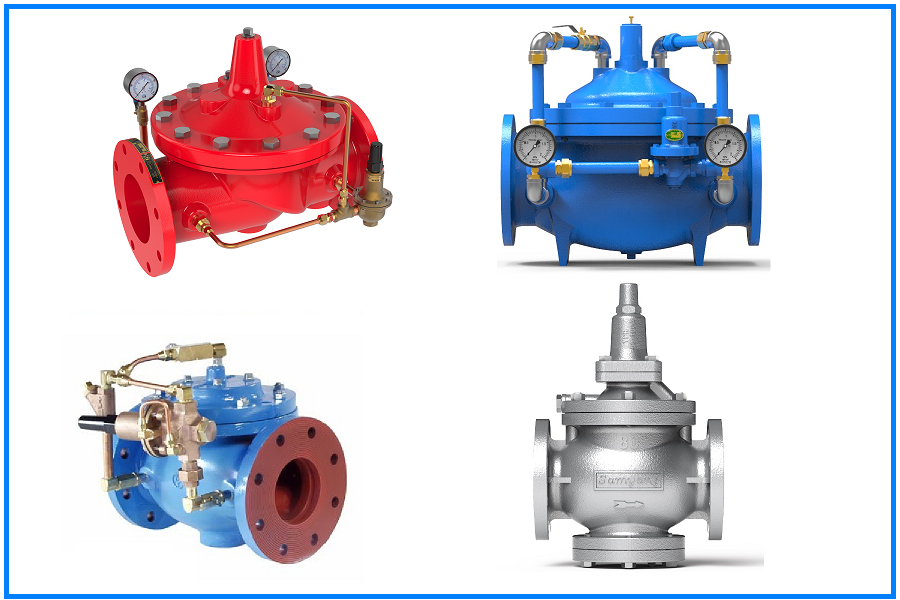

Pressure reducing valves, also known as pressure regulating valves, are critical devices in industrial piping systems that help control and maintain safe pressure levels, protecting equipment from damage due to overpressure. Below is a detailed analysis of the benefits, functions, and applications of pressure reducing valves.

What is a Pressure Reducing / Pressure Regulating Valve?

A pressure reducing valve (or pressure regulating valve) is a mechanical device installed in piping systems to regulate and maintain stable pressure levels. When the system pressure exceeds safe limits, the pressure reducing valve automatically lowers the pressure to protect the equipment and maintain system stability.

Functions of a Pressure Reducing Valve

- Pressure control: The primary function of the pressure reducing valve is to lower high input pressure to a lower output pressure, ensuring it meets the system's requirements.

- Equipment protection: These valves protect equipment such as pipelines, pumps, and other industrial devices from damage caused by excessive pressure.

- Pressure stabilization: They help stabilize the pressure within the system, ensuring safety for operators and preventing pressure-related incidents.

- Energy savings: Pressure reducing valves help eliminate unnecessary pressure in the system, optimizing energy efficiency and reducing operating costs.

Benefits of Using Pressure Reducing Valves

- High safety: Pressure reducing valves ensure that the system operates within safe pressure levels, minimizing the risk of accidents or industrial incidents.

- Automatic operation: These valves operate automatically, allowing operators to manage pressure control without manual intervention.

- System protection: By maintaining safe pressure, the system experiences less wear and tear, reducing maintenance costs and extending the life of the equipment.

- High flexibility: Pressure regulating valves are versatile and can be used in various systems, from water, steam, and air systems to oil and chemical processes.

Applications of Pressure Reducing / Pressure Regulating Valves

- Water industry: Pressure regulating valves are commonly used in water supply systems to control pressure and protect pipelines and pumps from overpressure incidents.

- Steam systems: In manufacturing plants, these valves control steam pressure to ensure safety and optimize production processes.

- Compressed air systems: They are also used in compressed air systems to regulate pressure and ensure the safety of air-operated devices.

- Oil and chemical industries: Pressure reducing valves are widely applied to adjust pressure levels in oil and chemical pipelines, protecting systems from pressure fluctuations.

Choosing Pressure Reducing Valves from Phuc Minh Engineering

Phuc Minh Engineering is a leading supplier in Vietnam, specializing in distributing high-quality pressure reducing valves from renowned brands such as VYC, Yoshitake, TLV, VENN, Samyang, Borady, Boscarol,... With years of experience, Phuc Minh guarantees optimal pressure valve solutions that meet technical and safety standards for all types of industrial systems.

- Wide product range: Phuc Minh offers a complete range of pressure reducing valves suited for various applications, from heavy industry to residential systems.

- Guaranteed quality: All products are rigorously tested and meet international safety and performance standards.

- Professional consultation: Phuc Minh’s team of experienced engineers is ready to assist customers in selecting, installing, and operating the appropriate pressure valve for their systems.

📞 Contact PME – Your Trusted Industrial Equipment Partner

Phuc Minh Engineering Co., Ltd (PME) specializes in:

✅ Supplying genuine industrial equipment, pumps, valves, and water treatment systems.

✅ Consulting, installation, and maintenance for factories and production lines.

Contact Information:

- 🌐 Website: www.pm-e.vn

- 📧 Email: info@pm-e.vn

- ☎️ Tel: +84 (28) 3535 2125 | Fax: +84 (28) 3535 0254

- 📍 Address: 92/38 Street No.12, KP18, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City, Vietnam

- 📱 Zalo: 0902 720 814 – 0907 450 506 – 0902 800 728 – 0979 737 351

👉 PME – Delivering Reliable Engineering Solutions for Every Factory in Vietnam.

Related News

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

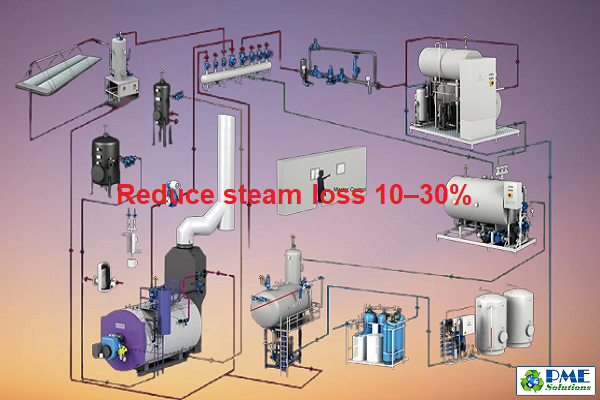

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

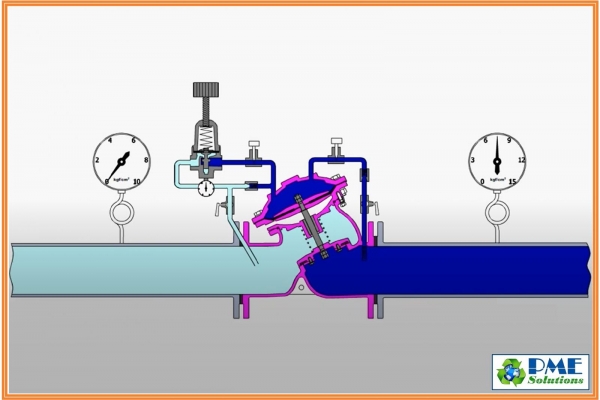

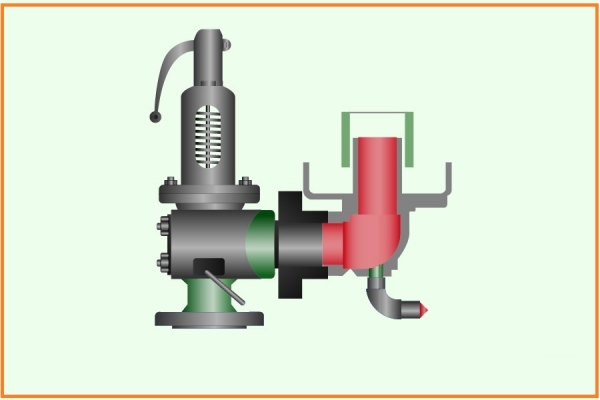

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

.png)