Technical corner

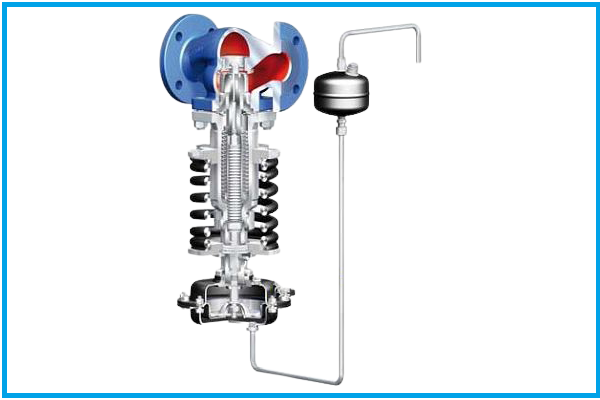

What Is a Steam Pressure Reducing Valve?

05/02/2025

A Steam Pressure Reducing Valve (PRV) is a device used in steam systems to reduce steam pressure from a high level to a stable, controlled level as required by the application. It helps regulate pipeline pressure, ensures equipment safety, and optimizes system efficiency. Applications of Steam Pressure Reducing Valves Steam PRVs are widely used across various industries such as: Power Plants: Controlling steam pressure supplied to turbines. Textile Industry: Providing suitable steam pressure for steamers and ironing machines. Food & Beverage Industry: Applied in cooking and steaming processes. Oil & Gas, Chemical Industry: Used in heating and chemical processing systems.

DIDTEK Steel Valves for Oil & Gas and General Industrial

25/11/2024

DIDTEK Valve Group, established in 1985, is one of China’s leading industrial valve manufacturers. The company is headquartered in Lin Yang Industrial Zone, Oubei Town, Yongjia County, Zhejiang Province. DIDTEK specializes in the design, production, and export of high-quality industrial valves, serving industries such as oil & gas, petrochemicals, power generation, marine, water treatment, and more. Main Products Gate Valves Globe Valves Ball Valves (Floating Ball Valves, Trunnion Mounted Ball Valves) Butterfly Valves Check Valves Knife Gate Valves Safety Valves Valves for high temperature, high pressure, and cryogenic applications

Types of Mechanical Valves in the Industrial Valve Industry: Advantages, Disadvantages, and Their Applications

15/10/2024

The industrial valve industry plays an important role in piping systems, helping to control and regulate the flow of liquids, gases, and steam. Below is an article about the common types of mechanical valves in the industrial valve industry: gate valves, globe valves, ball valves, butterfly valves, check valves, Y-strainers, needle valves, angle valves, diaphragm valves, and sanitary valves. We will analyze the advantages, disadvantages, and applications of each type of valve.

10 Most Important Industrial Equipment in Factories

15/10/2024

Modern industrial factories rely on a range of equipment to maintain high performance and ensure continuous operation. Below is a detailed description of the 10 most important types of industrial equipment, including their functions, applications, advantages, and disadvantages.

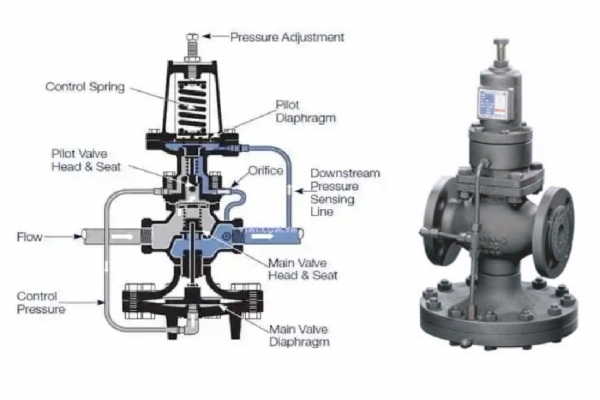

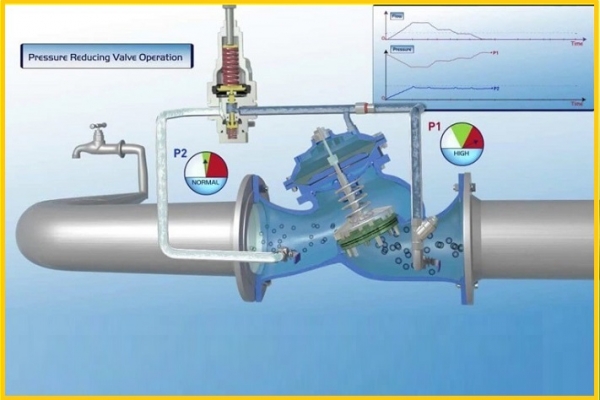

Operating Principle Of Samyang Korea Pressure Reducing Valve

15/10/2024

At the initial position, the valve is fully open, the width of the outlet is set by the adjusting screw. The effect of the valve almost keeps the output pressure value constant. In case the output pressure value increases in the hydraulic system; the pressure of the cavity connected to the valve outlet by the connecting groove also increases; pushing the control piston up reduces the cross-section of the outlet; leading to a decrease in the output pressure. When the output pressure decreases, the control piston goes down, increasing the cross-section of the outlet; leading to an increase in the output pressure.

Overview of Pressure Reducing Valves.

15/10/2024

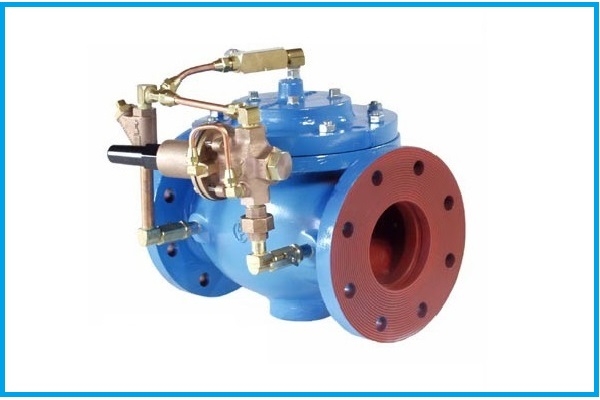

Overview of Pressure Reducing Valves. What is a Pressure Reducing Valve (PRV)? A Pressure Reducing Valve (PRV) is a device used to regulate and maintain the pressure in a system at a stable level, lower than the inlet pressure. PRVs work by reducing the pressure from a high-pressure supply to a pressure level that meets the system's requirements, helping to prevent overpressure and protect other equipment from damage. Pressure reducing valves are widely used in water, steam, gas and oil supply systems, both industrial and domestic.

What is a pressure reducing valve? Structure, Operating Principle, Adjustment and Classification of Pressure Reducing Valves.

02/10/2024

Pressure Reducing Valve is also known as pressure regulator, pressure stabilizer, pressure regulating valve, etc. It is a type of industrial valve installed on the pipeline, with the function of reducing pressure and stabilizing output pressure, so that the output pressure is always smaller than the input pressure of the system, helping fluids to be easily transmitted to different devices. but the pressure is not too different.

Benefits, Functions, and Applications of "Pressure Reducing Valves" / "Pressure Regulating Valves

02/10/2024

Pressure reducing valves, also known as pressure regulating valves, are critical devices in industrial piping systems that help control and maintain safe pressure levels, protecting equipment from damage due to overpressure. Below is a detailed analysis of the benefits, functions, and applications of pressure reducing valves.

Benefits and uses of safety valves

02/10/2024

Safety valves are essential devices in industrial systems, designed to protect equipment and ensure operator safety. Below is a detailed analysis of the benefits and applications of safety valves.

.png)