Demo video showing the operation of free float steam traps, disc steam traps, and orifice-type steam traps.

1. Free-Float Steam Trap

Overview

-

This is a mechanical steam trap that uses a float to operate the valve, often called a “float trap.”

-

We offers Free-Float traps in various types: low-pressure, medium/high-pressure, main line traps, and models with bypass valves.

-

Key advantages: continuous discharge, high back-pressure tolerance, durable design with few moving parts.

Construction

-

Float: We designs precision-ground spherical floats for tight sealing and minimal wear.

-

X-element (air vent section): Automatically vents air using a diaphragm and thermosensitive element. At low temperatures (cold condensate or air), the vent opens; at higher temperatures (steam), it closes.

-

Fail-Open Design: If the X-element diaphragm fails, the trap still opens to prevent condensate buildup, ensuring safety.

-

Three-Point Seating: Some main-line models use three-point float support to ensure sealing even with very low condensate flow.

Operation

-

Startup: When cold, the X-element contracts → vent opens → cold condensate and air are discharged.

-

Normal Operation: Condensate enters → float rises → main valve opens → continuous condensate discharge; X-element vents any air.

-

Low Condensate: X-element expands with steam → vent closes; float lowers → main valve closes → water seal prevents steam loss.

-

Diaphragm Failure: Fail-open design allows condensate to drain even if the diaphragm breaks.

Applications

-

Suitable for heat exchangers, reactors, jacketed kettles, dryers, and other steam equipment.

-

High back-pressure tolerance (~90%) makes our company Free-Float traps ideal for closed condensate recovery systems.

2. Disc / Thermodynamic Steam Trap

Overview

-

We’re disc-type steam traps are thermodynamic steam traps.

-

Popular models include ThermoDyne® A3N and PowerDyne® P-series, HR-series.

-

Advantages: minimal steam loss, simple design, easy maintenance, high-pressure tolerance, and resistance to scaling.

Construction

-

Valve Disc: Stainless steel, precision-lapped for tight sealing.

-

Bimetal Ring: Acts as an automatic air vent at cold startup; it contracts when cold and expands when heated.

-

Pressure Chamber: Operates based on pressure differential; some high-pressure models have a steam jacket to reduce thermal cycling.

-

Strainer: Built-in screen filters debris for long-term stable operation.

-

Replaceable Module: Valve assembly can be replaced without changing the entire trap, simplifying maintenance.

Operation

-

Cold Start: Bimetal contracts → disc held open → initial air and cold condensate are discharged.

-

Steam Flow: Steam enters → bimetal heats → disc lifts → steam jet creates low-pressure under the disc → disc closes.

-

Condensate Discharge: Condensate enters → pressure in chamber drops → disc lifts → condensate is discharged → steam re-enters → disc closes; cycle repeats.

-

No Condensate: Disc remains closed due to chamber pressure; some jacketed models reduce no-load cycling, prolonging service life.

Applications

-

Suitable for high-pressure steam lines, main lines, industrial steam equipment, jackets, coils, small boilers.

-

High-pressure models (e.g., HR-series) feature steam jackets to reduce heat loss and extend lifespan.

-

Simple structure with few moving parts ensures durability under harsh conditions.

3. Specific Product Examples

-

J3X‑10 Free Float Steam Trap: A free-float model suitable for low to medium pressure, widely used in industrial steam equipment.

-

HR80A PowerDyne Disc Steam Trap: A thermodynamic disc trap designed for high pressure, with a durable and tight-sealing construction.

Related News

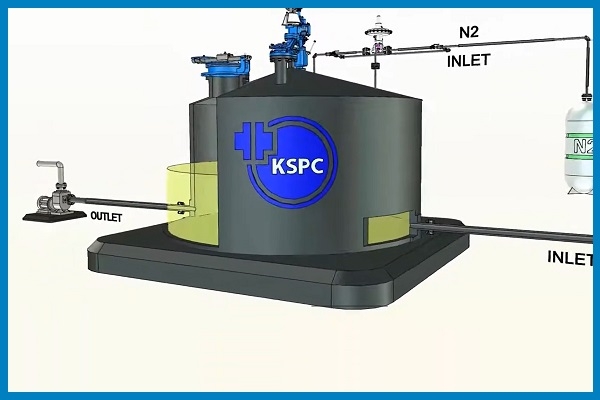

Demo video showcasing the operation of Breather Valves, Flame Arresters, Emergency Relief Valves, Nitrogen Blanketing Valves, and Sampling Devices

20/11/2025

KSPC provides a comprehensive system of advanced tank protection equipment, including breather valves, flame arresters, emergency relief vents, N₂ blanketing valves, and sampling devices. KSPC’s breather valves, such as the KSVR/VS series and combinations with flame arresters (e.g., KSVRFI-A), are designed according to API 2000 standards, protecting tanks from positive and vacuum pressures, reducing vapor loss, and preventing the release of odors or flammable gases. Flame arresters (such as the KSFI-A) are passive devices with no moving parts, using stainless steel flame cell elements to extinguish flames and prevent them from entering the tank. KSPC also develops emergency relief valves, such as the KSEVK or KSESV series, designed to relieve excessive pressure or vacuum in tanks, especially in emergency situations like fires. With N₂ blanketing valves (DST-100 series), KSPC helps maintain stable pressure within the tank vapor space, preventing the ingress of air and moisture, reducing the risk of fire, explosion, and product evaporation. Additionally, KSPC offers sampling devices to safely take liquid or gas samples from tanks without releasing pressure or vapor into the environment—enabling quality control or process monitoring (although the official KSPC website in Vietnam provides limited detailed information on the specific sampling device models).

Video about KSPC

20/11/2025

KSPC (Korea Steel Power Corp.) is a leading Korean manufacturer specializing in tank safety and protection devices, particularly for industrial systems involving flammable materials and pressure-sensitive storage tanks. Headquartered and operating its main factory in Gimpo, South Korea, KSPC has built a strong reputation for delivering reliable and high-performance safety solutions. The company provides a wide range of products, including pressure-vacuum breather valves, breather valves with flame arresters, nitrogen blanketing valves, flame arresters, emergency vent covers, and various tank protection equipment. All products are engineered and tested in accordance with API 2000 standards, ensuring optimal control of over-pressure, vacuum conditions, vapor losses, and fire risks. With extensive experience and advanced safety-valve technology, KSPC not only manufactures but also offers comprehensive services from design consultation to installation and maintenance. Since its establishment, the company has continuously expanded its capabilities—relocating its main factory in 2010 and opening its R&D center in 2014. KSPC holds major certifications such as KFI, ISO 9001, ISO 14001, and ATEX, demonstrating its commitment to global quality and safety requirements. Its products are widely used in petrochemical plants, chemical processing, natural gas systems, vapor recovery units, ignition systems, and industrial storage tanks.

.png)