Globe Valve – Phuc Minh Engineering

Globe Valve – Phuc Minh Engineering

Globe valve is one of the most common types of industrial valves, widely used to stop, regulate, and control the flow of liquids and gases in piping systems. In particular, globe valves are extensively applied in steam, hot oil, high-pressure compressed air, chemicals, and heavy industrial systems.

Currently, Phuc Minh Engineering proudly stands as a trusted distributor of high-quality industrial valves in Vietnam, including globe valves with competitive pricing, a wide variety of models, and guaranteed genuine products. With a team of experienced engineers, Phuc Minh always accompanies customers in consulting, selecting, and implementing the most optimal piping solutions.

What is a Globe Valve?

A globe valve (also known as a stop valve or hot steam valve) is an industrial valve designed to open/close or regulate the flow of liquids and gases within a pipeline.

The name "globe valve" originates from the disc’s shape, which resembles a globe. Its design enables precise flow regulation while ensuring excellent leak-tightness, even under high pressure and temperature applications.

Globe valves are commonly found in steam systems, hot oil systems, compressed air, chemical pipelines, hot–cold water, and industries that demand accurate flow control.

Key Advantages of Globe Valves

-

Efficient flow regulation: Precise control of flow rate with a rising–lowering disc mechanism.

-

Tight shut-off: Better sealing against fluid or gas leakage compared to many other valve types.

-

Variety of materials: Stainless steel, cast iron, brass, carbon steel, plastic… suitable for different working environments.

-

Wide applications: Steam, oil, chemical, clean water, high-pressure compressed air.

-

Easy maintenance: Simple disassembly and replacement of internal components.

Basic Components of a Globe Valve

A standard globe valve consists of:

-

Body: Withstands pressure and contains internal parts. Common materials: cast iron, steel, stainless steel.

-

Bonnet: Provides a tight seal and rigidity, while allowing easy removal for maintenance.

-

Disc: The element that directly opens/closes flow; available in cone, cylindrical, or flat shapes.

-

Stem: Transmits motion from the handwheel or actuator to the disc.

-

Actuator: Can be manual handwheel, electric actuator, or pneumatic actuator.

-

Packing/Gasket: Prevents fluid leakage outside.

Working Principle

When the handwheel is turned, the force is transferred to the stem, which lifts or lowers the disc.

-

Open state: Fluid passes through the space inside the body.

-

Closed state: The disc presses tightly against the seat, completely blocking flow.

This precise regulation makes globe valves particularly suitable for systems that require stable and accurate flow control.

Common Types of Globe Valves

By connection:

-

Flanged globe valve

-

Threaded globe valve

-

Welded globe valve

By body design:

-

Tee Globe Valve

-

Wye Globe Valve

-

Angle Globe Valve

-

Bellows Globe Valve

By actuation:

-

Manual globe valve

-

Electric actuator globe valve

-

Pneumatic actuator globe valve

By material:

-

Stainless steel globe valve (corrosion & chemical resistance, high temperature)

-

Steel globe valve (high-pressure, boiler, hot oil)

-

Cast iron globe valve (water, steam)

-

Brass globe valve (small-size, water, gas)

Technical Specifications (Reference)

-

Size: DN15 – DN1200

-

Pressure rating: PN16 – PN25 (higher available upon request)

-

Working temperature: -20°C to 450°C

-

Materials: Cast iron, steel, stainless steel, brass, plastic

-

Connections: Threaded, flanged, welded

-

Standards: DIN, ANSI, BS, JIS

Real Applications of Globe Valves

Globe valves are widely applied across many industries:

-

Steam and industrial boilers

-

Oil & gas, petrochemical, and chemical plants

-

Hot oil and high-pressure compressed air systems

-

Water treatment – water supply & drainage

-

Food & beverage processing

-

Textile dyeing, fertilizer, and paper industries

Why Choose Phuc Minh Engineering?

-

Authorized distributor of genuine, high-quality industrial valves

-

Wide range of brands: KSPC, Nacional, Conval, Klinger, Ritag, Dantec, …

-

Optimal technical solutions: consulting and product selection tailored for each system

-

Full CO-CQ certificates, meeting international standards

-

Competitive pricing and ready stock available in Vietnam

-

On-site technical support and warranty service

Contact for Consultation & Quotation

If you are looking for genuine, high-quality Globe Valves at competitive prices, please contact:

Phuc Minh Engineering Co., Ltd.

🌐 Website: www.pm-e.vn

📞 Hotline: +84 902 800 728

👉 With years of experience in the industry, Phuc Minh is committed to providing customers with the most optimal industrial valve solutions, ensuring performance, durability, and safety for your entire system.

Related News

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

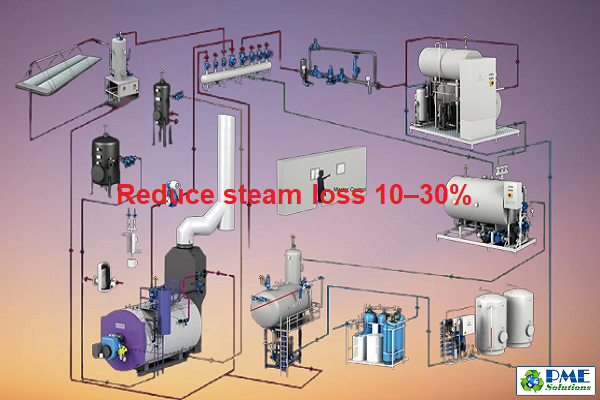

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

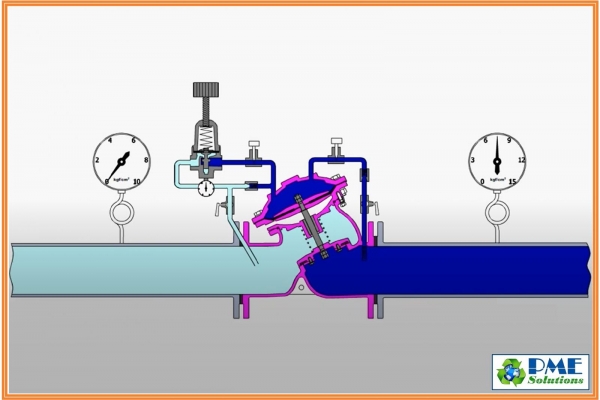

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

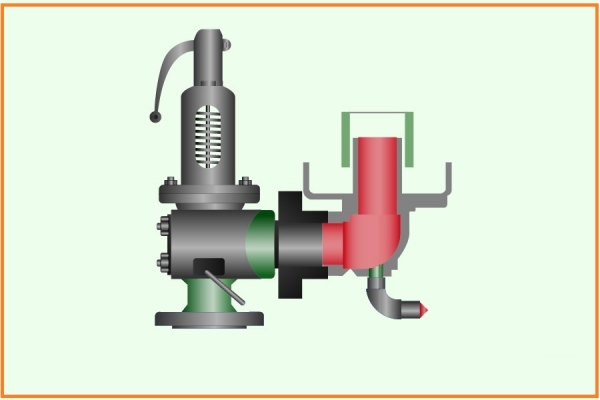

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

.png)