What Is a Breather Valve?

Structure, Function, and Operating Principle

-

What Is a Breather Valve?

A breather valve, also known as a pressure-vacuum relief valve (PVRV), is a safety device that protects storage tanks from explosion or collapse caused by pressure differences. It is typically installed on top of storage tanks for fuels, chemicals, LPG, or gases..jpg)

KSBB -

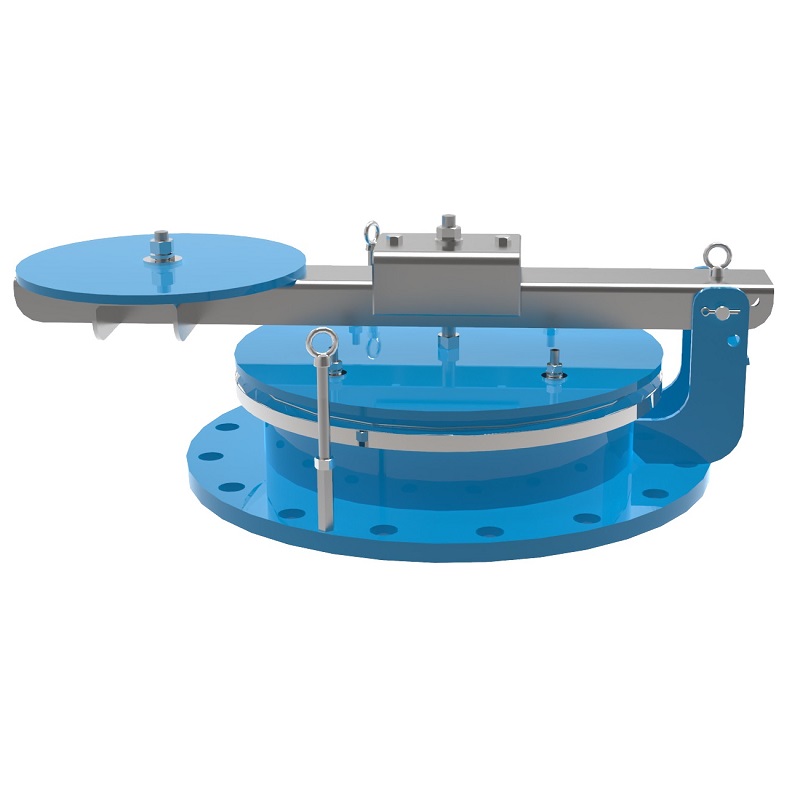

Structure of a Breather Valve

A breather valve consists of the following main components:

-

Valve Body: Made from steel, stainless steel, aluminum, or cast iron, designed to withstand pressure and harsh environments.

-

Valve Cap: May include or exclude a flame arrester.

-

Spring or Weighted Disc: Regulates the valve’s opening pressure.

-

Sealing Gasket: Ensures gas or vapor only escapes when the set pressure is reached.

-

Flame Arrester (Optional): Prevents flames from entering the storage tank.

KSPR KSVR

-

Functions of a Breather Valve

-

Releasing Excess Pressure: When internal tank pressure exceeds the set threshold, the valve opens to release gas, preventing tank explosion.

-

Drawing Air into the Tank: When internal pressure drops below safe levels, the valve opens to let air in, preventing tank collapse due to vacuum.

-

Preventing Solvent Vapor Loss: Protects the environment and reduces fuel loss.

-

Integrated Flame Arrester: Safeguards tanks from fire or explosion caused by sparks or sudden pressure surges.

-

Operating Principle of a Breather Valve

The breather valve operates based on the pressure differential between the inside of the tank and the external environment:

-

When internal pressure exceeds the set point: The force on the valve disc surpasses the spring force, causing the valve to open and release gas. When pressure returns to a safe level, the valve automatically closes.

-

When internal pressure drops (vacuum forms): External atmospheric pressure is higher than inside the tank, causing the valve to open and allow air in. Once pressure is balanced, the valve closes.

KSBBFI

-

Types of Breather Valves

-

Pressure-Vacuum Relief Valve: The most common type, protecting tanks from both overpressure and vacuum.

-

One-Way Breather Valve: Allows airflow in only one direction, either in or out.

-

Breather Valve with Flame Arrester: Used in flammable or explosive environments.

-

Emergency Breather Valve: Activates during sudden overpressure incidents.

KSEPK

-

Applications of Breather Valves

-

Oil and Gas Industry: Installed on fuel, oil, LPG storage tanks to control pressure.

-

Chemical Industry: Protects chemical storage tanks from volatile substance loss.

-

Food and Pharmaceutical Industry: Controls vapor and protects storage environments.

-

Compressed Air and Gas Storage: Ensures safety in high-pressure systems.

Breather valves are essential devices that maintain safe pressure levels in liquid or gas storage systems, preventing explosion risks and fuel loss.

Contact: PHUC MINH TECHNICAL CO., LTD. for reliable, high-quality industrial valve solutions.

Email: duong@pm-e.vn

Cellphone/Zalo: +84 902 499 190

Address: 92/38, Street No.12, KP18, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City, Vietnam.

Related News

FDA-Approved Rubber Gaskets – Safe Solutions for Food & Medical Applications

23/04/2025

FDA-Approved Rubber Gaskets – Safe Solutions for Food & Medical Applications Phuc Minh Engineering Co., Ltd. is proud to be one of the leading distributors in Vietnam of rubber gaskets for food and medical applications. Our products are made from high-quality materials and meet the strict FDA (U.S. Food and Drug Administration) standards – ensuring safety for direct contact with food and medical equipment.

HIGH-TEMPERATURE GASKETS – UP TO 1000°C WITH THERMa-PUR™ 4122 MATERIAL

23/04/2025

HIGH-TEMPERATURE GASKETS – UP TO 1000°C WITH THERMa-PUR™ 4122 MATERIAL In many heavy industries such as chemical processing, oil refining, cement, and power generation, sealing materials must endure extreme temperatures, high pressure, and harsh oxidative environments. Phuc Minh Engineering Co., Ltd. is proud to be a distributor of high-temperature gaskets rated up to 1000°C, combining Garlock’s advanced THERMa-PUR™ 4122 material with Corrugated Metal Gaskets (CMG) – delivering an optimal sealing solution for extreme industrial conditions.

Trusted Industrial Valve Distributor – Industry Leader

26/02/2025

With the continuous growth of Vietnam's economy, the demand for industrial valves and related technical solutions has significantly increased. In this article, we would like to introduce a reputable and leading industrial valve distributor in this field — Phuc Minh Engineering Co., Ltd.

Top 10 best water flow meter brands today

12/02/2025

Sensus water flow meter: Origin: Germany. Advantages: The product has high precision, durable design and stable operation in many different environmental conditions. Sensus clocks are certified by European CO, CQ, suitable for large-scale projects.

What Is NBR Rubber?

05/02/2025

What Is NBR Rubber? NBR (Nitrile Butadiene Rubber) is a synthetic rubber created through the copolymerization of acrylonitrile and butadiene. It is renowned for its excellent resistance to oil, solvents, and various chemicals, making it widely used in industrial applications.

.png)