Industrial Valve Operating and Troubleshooting Procedures

Today, the industry in Vietnam is on a strong development path, and declines in production processes have become common. Along with this development, industrial equipment such as industrial valves, pressure gauges, flow meters and temperature gauges have become more familiar and easily accessible. Nowadays, more and more new industrial equipment suppliers are blooming, and consumers also have more choices when buying industrial equipment.

Concept of industrial valves

Industrial valve is a mechanical device widely used in industry, especially in pipeline systems. The main function of a valve is to regulate the flow of fluid through the system. Despite their simple and sturdy structure, industrial valves play an important role in modern factories and plants. However, not everyone knows how to operate them.

.jpg)

Industrial valves are often designed to be used for long periods of time without problems or damage. The process of opening and closing the valve must take place slowly and steadily. If the valve opens or closes too quickly, the temperature and pressure in the pipeline can change suddenly, causing damage to the system.

Popular types of industrial valves

On the market today, there are many types of industrial valves commonly used as follows:

Globe Valve: This type of valve is used to regulate the flow of fluid in the system and is usually designed for long-term use.

Ball Valve (2-Way Valve, 3-Way Valve...): These types of ball valves are often used to control flow by opening and closing with a ball.

One-Way Valve (Lift Valve, Two-Way Disc Valve, Recirculating Disc Valve...): This valve prevents backflow in the system, helping to maintain pressure.

Gate Valve, Gate Valve: This type of valve is often used to control flow by raising and lowering the gate.

Butterfly Valve (Electric Butterfly Valve, Wafer Butterfly Valve...): Butterfly valve uses a butterfly blade to control the flow of fluid.

Knife Valve: This type of valve is designed to cut off fluids and is often used in special applications.

Safety Valve: These safety valves are used to protect the system from excessive pressure.

Pressure Reducing Valve: This type of valve helps reduce pressure in the pipeline system.

Control Valves: These valves are used to regulate the flow and other parameters of the fluid in the system.

Oblique Valve: This type of valve has an inclined angle and is used in special applications.

Solenoid Valves: Solenoid valves are electrically controlled to open and close flow.

Additionally, some types of industrial valves require periodic lubrication to ensure smooth operation.

.jpg)

Troubleshooting industrial valves

Most valve operators do not have the ability to repair valve failures, but they need to determine the cause of the failure in order to notify the repair team. This requires them to be skilled in detecting the causes of failures.

Faults in manually operated valves are often easy to identify, such as broken rotors or dislodged threads. If these mechanisms still function normally but still cannot control the valve, it means that damage has occurred inside the valve.

With one-way valves, there is usually no damage on the outside. Therefore, when a check valve does not prevent reverse flow, it means the valve has failed internally.

With control valves, it is often more difficult to determine the cause of the failure. If the control valve is broken, the first thing to do is check the signal from the control device to the control mechanism. If the signal is still correct, the cause of the failure may lie in the control device.

Sometimes, the signal from the control device to the control mechanism is disturbed due to a leak or blockage between these two components. Therefore, the control valve may be damaged in the signal transmission system. Most control valves are equipped with a valve position device.

By looking at the valve positioner, you can see the current position of the valve. Suppose that the control device is sending a signal to close the valve, but you still hear the flow through the valve. If the position finder indicates that the valve is in the closed position, you can determine that the failure is on the inside of the valve body.

This may also indicate that the valve is clogged or that the seal has worn too much. However, if the position finder indicates that the valve is in the open position, the failure may originate from other parts, such as the valve stem being stuck in the sealing chamber cover, or the control mechanism not being properly positioned. works fine. Problems may come from the positioning mechanism if any.

When the valve has a positioning mechanism, you need to check this device as well. This is usually done by checking the input and output signals of the positioning mechanism. For control valves, if they are broken, you usually start checking from the control device and then work your way down to the valve.

.jpg)

Suggestions when using industrial valves

- Choose the appropriate valve stem size to ensure they are tightly fixed to the crank and avoid them slipping out during operation.

- Make sure to balance your body position when applying force to the valve stem to avoid the risk of falling when opening the valve too quickly.

- When using, stand behind and pull the valve stem towards you instead of pushing it away, avoiding the risk of falling when opening the valve too quickly and ensuring the safety of others around.

- Do not apply too much force when operating the valve with the valve stem to avoid damaging or affecting the valve and other sealing parts.

- Industrial valves require periodic lubrication, ensuring that threads and related parts are lubricated regularly to maintain good operation.

How to handle industrial valve problems

In the event of a problem with an industrial valve, troubleshooting should be done carefully and according to safety procedures. Operators need to:

- Immediately stop using the valve when detecting problems or damage.

- Notify a repair team or professional to identify and fix the problem.

- Avoid testing or repairing the valve yourself if you do not have enough knowledge and skills.

- Follow all safety instructions and procedures when troubleshooting.

.jpg)

Conclude

The operation and maintenance of industrial valves is a vital part of the industrial process and requires understanding and skill. To ensure system safety and performance, operators need to know how to operate properly, perform routine maintenance, and know how to troubleshoot when necessary.

PHUC MINH ENGINEERING COMPANY LIMITED

Hotline: +84902800728

Tel: +842835352125

Email: info@pm-e.vn

Website: www.pm-e.vn

Related News

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

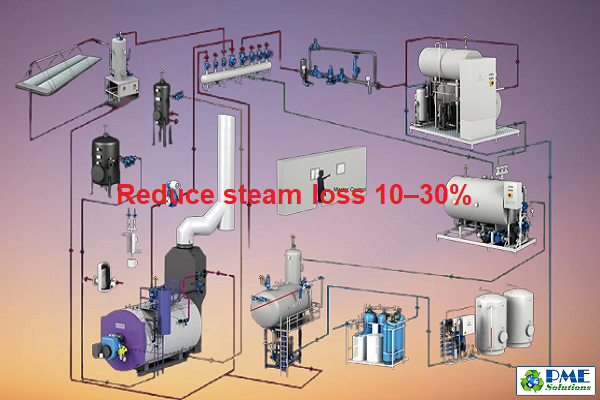

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

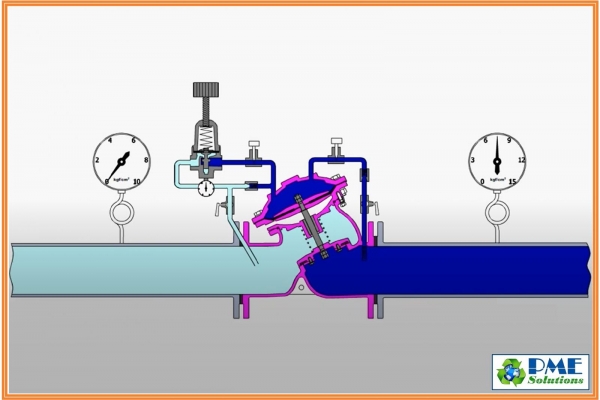

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

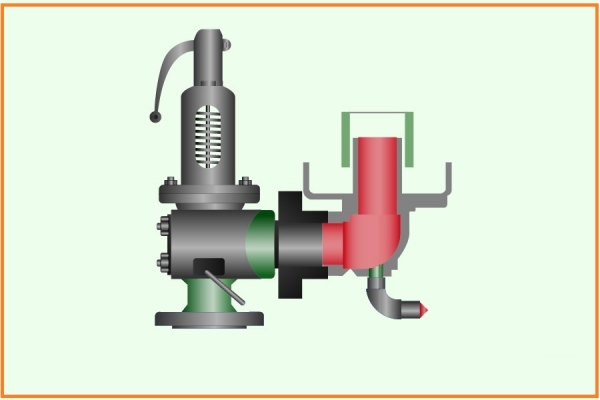

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

.png)