Largest Stockist Of PTFE On Ex Stock Basis At The MOST COMPETITIVE PRICE

Largest Stockist Of PTFE On Ex Stock Basis

At The MOST COMPETITIVE PRICE

We are the leading distributor of PTFE & Engineering Plastics Semi-Finished Products and Chemical Water Tanks

Industry's Leading PTFE Supplier

Being the largest stockist, we supply a wide range of high-quality engineering plastics, PVC material and other industrial-grade plastics to support marketing at any time. In line with eco-friendly installations, we provide an extensive range of water tanks, chemical tanks and the latest rain harvesting systems for companies pursuing anti-pollution systems and rain harvesting systems.

We supply the best quality products on an

ex-stock basis at the most competitive prices.

All materials sold, with few exceptions, can be recycled as plastic scraps for alternative applications.

PTFE (Polytetrafluoroethylene)

Products

Polytetrafluoroethylene (PTFE) products exhibit versatile characteristics, showcasing excellent chemical resistance, low friction properties, corrosion protection, and high thermal stability.

.jpg)

Engineering plastics surpass the capabilities of most commodity plastics, providing excellent mechanical strength, electrical properties, and chemical and thermal resistance.

Polyvinyl chloride (PVC) curtains are long and narrow strips of plastics used to create transparent barriers or partitions, providing separations while allowing visibility and easy access.

PME’s PE roto moulded tanks are one-piece seamless tanks which are flexible, corrosion resistant, and can withstand normal expansion and contraction without breaking or shattering.

Why Choose Us?

Extensive Product Range

PME are a one-stop shop for all industrial plastic needs. With us, you can ensure a convenient and efficient sourcing process. Our extensive range of products includes PTPE, engineering plastics, PVC curtains and doors, and chemical tanks.

Quality Assurance

At PME, we source our products from trusted manufacturers and ensure every item meets stringent quality standards. Our commitment to quality assurance remains steadfast, as we provide our customers with peace of mind in their purchases.

Competitive Pricing

PME offers our customers the best value for their money without compromising on quality. By leveraging our strong relationships with our suppliers and economies of scale, we can provide cost-effective solutions for our customers.

Excellent Customer Service

PME values building strong customer relationships. We provide excellent support throughout the purchasing process, from product inquiries to after-sales assistance. Our team is always ready to assist you to ensure a smooth experience.

Industries We Serve

PME provides high-quality solutions for a wide range of industries, including:

Semiconductor

With exceptional electric insulation properties, thermal stability, and chemical inertness, our PTFE and engineering plastic products are widely used in the semiconductor manufacturing industry. From PTFE sheets and rigid tubes to PVC rods, these materials offer superior protection against corrosive acids, chemicals, and electrostatic shocks. This makes them ideal for safeguarding sensitive and demanding components in high-purity fluid handling systems, such as semiconductor trays, boxes, circuit boards, and more.

Chemical

Designed with high temperature and corrosion resistance, our engineering plastics and PTFE products are ideal for chemical manufacturing and processing sectors. These materials help protect components frequently exposed to harsh acidic or alkaline environments, including pipes, vessel linings, manifolds, pumps and valves, seals, bellows, tanks, drain-waste-vent systems, and laboratory equipment. We also offer PE roto moulded or blow-moulded tanks for safe and secure chemical storage or transportation.

Marine & Offshore

Our PTFE (Teflon®) products and engineering plastics offer excellent resistance to corrosion and aggressive chemicals, with non-stick properties and a low coefficient of friction. These features make them suitable for marine and offshore applications where exposure to saltwater and moisture is a concern. We offer a wide range of PVC marine-grade sheets, rods, and other materials for hatches, dock bumpers/fenders, cowls, and more. These products ensure long-term use and allow for applications in harsh environments. We also offer PE roto moulded tanks, ideal for water transportation tanks.

Industrial

Our engineering plastics and PTFE products exhibit excellent mechanical strength, minimal friction coefficients, chemical resistance, and low wear properties. From slide bearings and gears to pumps and other moving parts, our products offer protection against corrosive agents to guarantee optimal and long-lasting performance for industry machinery, conveyor systems, and material handling systems.

Pharmaceutical

Due to their non-reactive and lightweight properties, our high-quality PVC products are preferred materials for pharmaceutical applications. We offer medical-grade PVC sheets and films for the sterile packaging of medications, such as tablets and capsules, to ensure product safety. Since they are chemically inert, these materials can also be used for packing medical equipment, including tray lids and pouches, ampoule vials, syringes, wound dressings, diagnostic kits, and procedure kits.

Construction

With their durability and corrosion and abrasion resistance, our products are ideal for construction applications, including electrical insulation, sealing, and structural components for buildings.

Electrical

From wire insulation to semiconductor parts to circuit boards, our PTFE products are widely used in the electrical industry. They provide excellent electrical insulation properties, which can withstand high temperatures and corrosive chemicals.

Related News

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

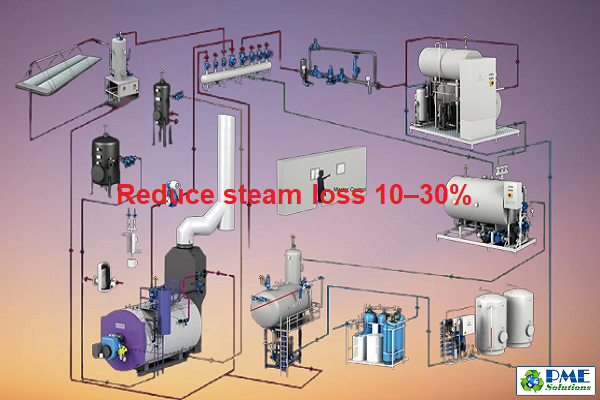

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

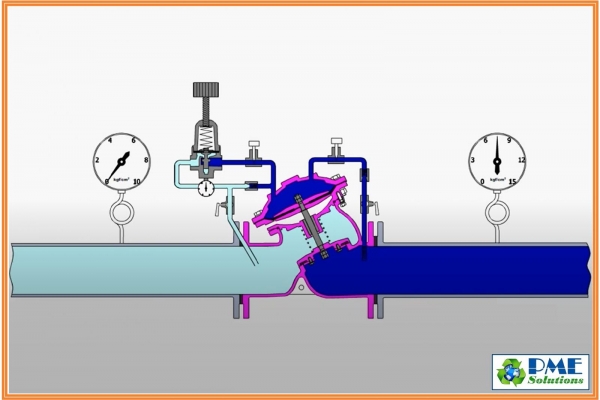

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

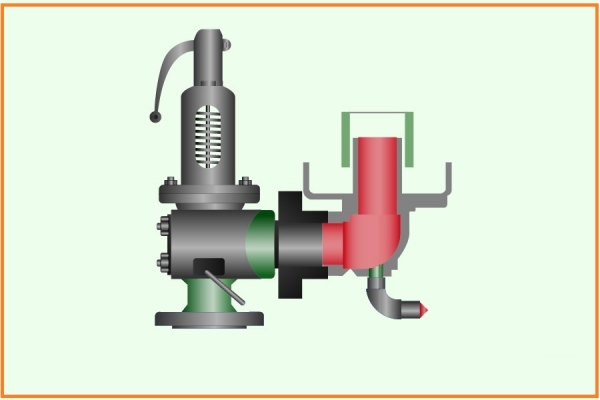

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

.png)