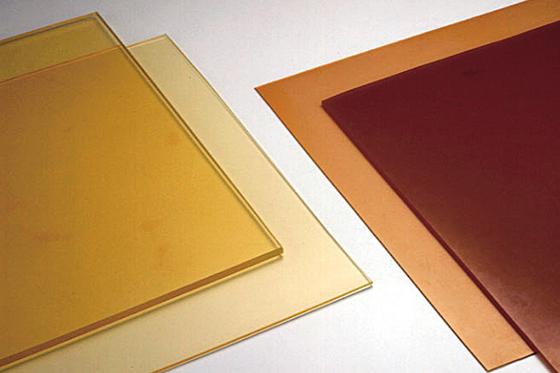

Polyurethane rubberUrethane Rubber Sheet (Ti-Prene Sheet)

Polyurethane rubberUrethane Rubber Sheet (Ti-Prene Sheet)

| Function | ・ Mechanical Strength ・ Impact Resilience ・ Abrasion Resistance ・ Ozone Resistance ・ Oil Resistance |

|---|

About Urethane Rubber Sheet (Ti-Prene Sheet)

Rubber-like elastic bodies obtained by the reaction of polyester or polyether with isocyanate are collectively called urethane rubber. Ti-Prene® is a trademark of our urethane rubber.

Features

Mechanical Strength: Due to its chemical structure, it has a strong secondary bond between molecules, so it has the highest strength among elastic bodies, and because of its high modulus, it is to be less deformed and can withstand heavy loads even with small objects. Due to its high hardness and high elongation, it is to be less susceptible to damage due to impact.

Abrasion Resistance: It has more than 10 times more abrasion resistance than natural rubber. It is to be superior to metal in some conditions of use.

Oil Resistance: It has excellent resistance to most oils, including petroleum-based oils. Especially excellent for mineral oil (only for use at room temperature).

Heat Resistance: The using limit temperature is 70 ° C. Avoid using continuously at 70 ° C or more.

Cold Resistance: It has rubber elasticity and mechanical strength even at -25 ° C or less.

Water Resistance: Please avoid using it in a hot and humid environment because it has the property of being easily hydrolyzed.

Ozone Resistance: It is hardly affected by ozone because it does not contain unsaturated parts in its molecular structure.

Weather Resistance: Please be noted that when used outdoors for a long period of time, the effects of water, humidity, light, etc. may cause deterioration of physical properties and discoloration.

Applications

・General packing, gasket material.

・Cushion material.

・Coupling.

・Bush.

・Scraper.

・Base material for rollers.

・Spring, dice.

*It does not meet food hygiene tests.

*Hardness measurement is revised to “After 3 seconds” according to JIS K 6253 (2006). However, generally, the conventional "measurement within 1 second" is to be the mainstream for nominal hardness, so this result is measured value and the measurement result after 3 seconds is shown in ().

Properties: Urethane Rubber Sheet

| Item Name |

Properties | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| General Properties | Tensile Stress M300 MPa {kgf/cm2} |

Tear Resistance kN/m {kgf/cm} |

Comp- ression Set 70°C × 24h % |

Abrasion Loss cc/1000 times |

Impact Resilience % |

Remarks | |||

| Hardness Type A |

Tensile Strength at Break MPa {kgf/cm2} |

Elongation at Break % |

|||||||

| TR100-90 | 91(89) | 52.1 {531} |

430 | 21.2 {216} |

90.3 {92} |

27 | 0.080 | 34 | Standard material (Polyester basis) |

| TR100-70 | 70(69) | 27.7 {283} |

630 | 3.6 {36.7} |

36.4 {37} |

28 | 0.200 | 50 | |

| TR100-60 | 60(60) | 23.7 {242} |

740 | 3.2 {33} |

36.6 {37} |

37 | 0.300 | 40 | |

| TR100-50 | 50(50) | 26.6 {271} |

610 | 2.5 {26} |

28.6 {29} |

10 | 0.100 | 31 | |

| TR200-90 | 91(89) | 35.1 {358} |

430 | 21.7 {221} |

86.8 {89} |

30 | 0.370 | 37 | Standard material (Polyether basis) |

| TR1000-90 | 90(90) | 42.0 {429} |

450 | 16.0 {163} |

74.7 {76} |

24 | 0.080 | 50 | Special grade (Polyether basis) |

- JIS K 6250

- ●Abrasion loss is by Akron abrasion test.

- ●Please consult us about various grades other than listed above.

Ti-Prene Sheet

Dimension

| Thickness (mm) |

Tolerance (mm) |

Thickness Deviation (mm) |

Width (m) |

Length (m) |

TR200-90 | TR100-90 | TR100-70 | TR100-60 | TR100-50 |

|---|---|---|---|---|---|---|---|---|---|

| 1 | +0.15 -0.1 | 0.2 | 1 | 2 | ○ | ○ | ○ | ○ | ○ |

| 1.5 | +0.15 -0.1 | 0.2 | ○ | ○ | ○ | ○ | ○ | ||

| 2 | +0.2 -0.1 | 0.2 | ○ | ○ | ○ | ○ | ○ | ||

| 3 | ±0.2 | 0.2 | ○ | ○ | ○ | ○ | ○ | ||

| 4 | ±0.2 | 0.2 | ○ | ○ | ○ | ○ | ○ | ||

| 5 | +0.3 -0.2 | 0.3 | ○ | ○ | ○ | ○ | ○ | ||

| 6 | +0.3 -0.2 | 0.3 | ○ | ○ | ○ | ○ | ○ | ||

| 7 | ±0.3 | 0.3 | ○ | ○ | ○ | ○ | ○ | ||

| 8 | ±0.3 | 0.3 | ○ | ○ | ○ | ○ | ○ | ||

| 9 | ±0.3 | 0.3 | ○ | ○ | ○ | ○ | ○ | ||

| 10 | ±0.3 | 0.3 | ○ | ○ | ○ | ○ | ○ | ||

| 12 | ±0.4 | 0.4 | ○ | ○ | ○ | ○ | ○ | ||

| 15 | ±0.5 | 0.5 | ○ | ○ | ○ | ○ | ○ | ||

| 20 | +1.5 0 | 0.8 | ○ | ○ | ○ | ○ | ○ | ||

| 25 | +1.5 0 | 0.8 | ○ | ○ | ○ | ○ | ○ | ||

| 30 | +1.5 0 | 0.8 | ○ | ○ | ○ | ○ | ○ | ||

| 35 | +2.0 0 | 1.0 | ○ | ○ | ○ | △ | △ | ||

| 40 | +2.0 0 | 1.0 | ○ | ○ | ○ | ○ | ○ | ||

| 45 | +2.5 0 | 1.5 | ○ | ○ | ○ | △ | △ | ||

| 50 | +2.5 0 | 1.5 | ○ | ○ | ○ | ○ | ○ | ||

| 55 | +2.5 0 | 1.5 | 1 | 1 | ○ | △ | △ | △ | △ |

| 60 | +2.5 0 | 1.5 | ○ | ○ | △ | △ | △ | ||

| 70 | +2.5 0 | 1.5 | ○ | ○ | △ | △ | △ | ||

| 80 | +3.0 0 | 2.0 | ○ | △ | △ | △ | △ | ||

| 90 | +3.0 0 | 2.0 | ○ | △ | △ | △ | △ | ||

| 100 | +3.5 0 | 2.0 | ○ | △ | △ | △ | △ |

- ○: Available △: Please consult us.

- ●Please consult us on grades and sizes other than listed above.

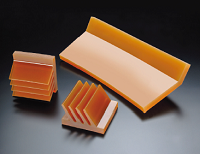

Ti-Prene Round Rod / Pipe

Round Rod

| Diameter(mm) | Length(m) | Grade(mm) |

|---|---|---|

| 10,15,20,25, 30,35,40,45,50, 60,70,80,90,100 |

1 | TR200-90 TR100-90 TR100-70 TR100-60 TR100-50 |

Pipe

| Outer Diameter(mm) | Innar Diameter(mm) | Length(mm) | Grade(mm) |

|---|---|---|---|

| 30,40,50, 60,70,80,100 |

10~60 | 0.5 | TR200-90 TR100-90 TR100-70 |

- ※Please consult us on grades and sizes other than listed above.

Ti-Prene Molded Products

*Please contact us.

CONTACT

•These products should not be incinerated wherever possible because harmful gas to humans might be generated if they are immoderately burned. •The user is requested to confirm degree of discoloration and contamination by using sample in the case of use contacting with the other items. •The life of these products at actual use are greatly affected by condition of the use. The user is requested to confirm it by using sample in the case of use under severe condition.

Please check here to find out the environmental compliance of this product.

●These descriptions can be altered for a reason of improvement without any notification. ●These descriptions shall be as of November 1, 2021.

Related News

VinVal Industrial Water Valves: Stainless Steel Globe Valves & Pipeline Solutions from PM-E

20/12/2025

Discover high-quality VinVal industrial water valves. PM-E specializes in providing stainless steel globe valves and diverse fluid control solutions for your pipeline systems.

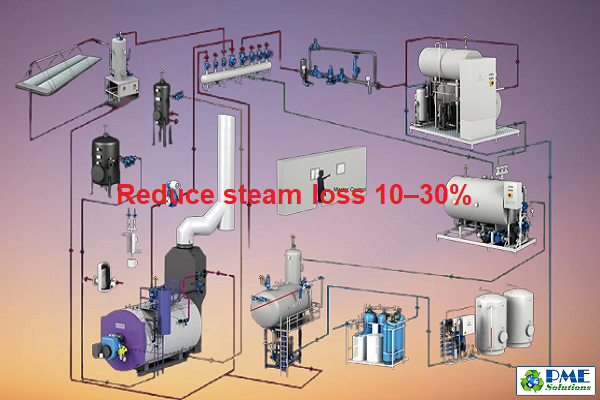

Steam Energy-Saving Solutions for Factories | Phuc Minh Engineering

17/12/2025

Optimize your steam system with Phuc Minh Engineering. Reduce energy loss, increase boiler efficiency, and cut fuel costs by 10–30%. Contact us now.

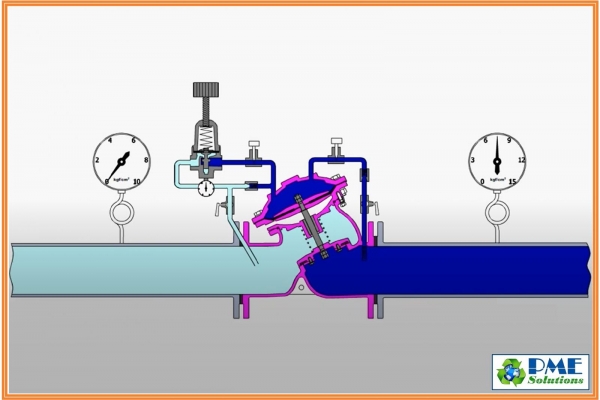

Flow Measurement & Pressure Control Solutions.

17/12/2025

Solutions for measuring flow and controlling pressure in steam, air, water, oil, and chemical systems. Optimize operations – reduce losses – enhance safety. Contact Phuc Minh.

What Is a Pressure Reducing Valve? Structure – Working Principle – How to Select the Best PRV for Industrial Plants (2025)

17/12/2025

A Pressure Reducing Valve (PRV) is a device used to reduce high inlet pressure to a stable, lower outlet pressure, helping protect piping systems, instruments, and machinery while improving operational safety. PRVs are widely used in: Steam systems Compressed air, gas, nitrogen Clean water – process water – chilled water Oil, chemicals, and other industrial media

Safety Valve For Steam Systems: Structure, Operation Principles & Selection Guide 2025 | Phuc Minh Engineering

17/12/2025

Learn what a steam safety valve is, how it works, different types, and how to select the correct valve for boilers and pipelines. EN/ASME-standard valves from Phuc Minh Engineering.

.png)