Chemical & Water Tanks - PVC Curtains & Doors

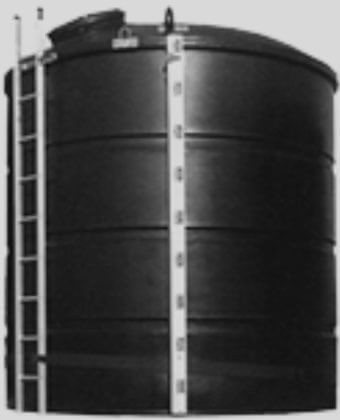

Chemical & Water Tanks

All tanks supplied by PME are either rotomoulded or blow moulded.

PE rotomoulded or blow moulded tanks are one piece seamless tanks produced from polyethylene using rotational moulding or blow moulding process which offer superior quality as they are corrosion resistant, flexible and will not break or shatter under normal expansion and contraction. PE tanks are competitively priced and suitable as storage and transportation tanks for a wide range of chemicals and can be used by water and wastewater industries and any industry that require storage or movement of chemicals.

Polyethylene resins used to manufacture PE tanks is an ethylene octane copolymer specifically designed for applications requiring excellent environmental stress crack resistance and impact strength combined with low warpage. It is fully head and UV stabilized resulting in good colour retention and long life expectancy. The resins comply with U.S. FDA 21 CFR 177.1520©3.1a.

Close Top Tanks

PE Rotomoulded Tanks

Ideal for use as water or chemical tanks due to inert nature of PE (Polyethylene) to most chemicals. However due to the basic origin of its resins, it is unsuitable for hydrocarbon based solvents. IBCs are excellent transportation tanks and are blow moulded from PE material.

-

Product Features & Advantages

-

Range of Tanks and Dimensions

-

Cylindrical Closed Top Tanks

-

Cylindrical Open Top Tanks

-

PE Resin Specifications

-

General Chemical Resistance Chart

-

Fittings and Accessories Available

Open Top Tanks

PE Rotomoulded Tanks

Ideal for use as water or chemical tanks due to inert nature of PE (Polyethylene) to most chemicals. However due to the basic origin of its resins, it is unsuitable for hydrocarbon based solvents. IBCs are excellent transportation tanks and are blow moulded from PE material.

-

Product Features & Advantages

-

Range of Tanks and Dimensions

-

Cylindrical Closed Top Tanks

-

Cylindrical Open Top Tanks

-

PE Resin Specifications

-

General Chemical Resistance Chart

-

Fittings and Accessories Available

IBC - Intermediate Bulk Containers

The ideal transportation tank for chemicals. Our IBCs are made from blow moulding in a single bottle and has the following advantages:-

-

Space saving innovation. 4 drums each with a volume of 200 litres, utilise the same space as a 1000 Litre IBC. A minimum of 20% better space utilisation.

-

The IBC meets international transport standards and regulations as well as providing an excellent fill in ISO-Containers. Their low tare weight is a further financial benefit during transport.

-

The IBC is easy to handle and can be stacked 3 high quite safely with liquids up to 1.3 S.G. It is easy to load or unload by use of fork-lift, pallet truck or crane, thus ensuring the best use of time and resources.

-

The specifically designed discharge valves guarantee safe and precise control of contents during emptying. The alternative discharge diameters allow products of very different viscosities to flow freely. The various types of valve options are all screwed-on to facilitate reconditioning.

-

Nowadays one of the most important considerations affecting packaging system selection is in its value after the initial journey. The IBC can be filled and shipped many times thus making it a fully reusable and therefore a multi-trip package.

-

The IBC offers the ideal module system incorporating easy-to-fit exchangeable plastic, metal or timber components. This enables the container to be used repeatedly but ensures simple and economic refurbishment when necessary. Finally disposal of waste and the return of product to the raws material cycle is made easier.

-

Available in steel or plastic pallets.

Rain Harvesting System

PFA RHS is specially designed for urban rainwater harvesting.

PFA RHS system essentially integrates modern aesthetical values, performance, reliability and simplicity to harvest free and abundant rainwater for all non-profitable applications in residential, commerical or industrial developments.

PFA RHS system, comprising of a complete range of product and accessories, offers various designs of proprietary PFA RHS tanks for both indoor and outdoor use; as well as PURITY pre-filters and accessories to remove sendiments from the rainwater and controls the waterflow before entering into the storage tanks.

PVC Curtains & Doors

PE Rotomoulded Tanks

-

PVS Curtain strips for curtain doors from 2mm to 5mm

-

PVC clear rools

-

S.S Accessories for installation of curtain strips

-

Stainless steel

Related News

Industrial Valves for Chemical Plants, Oil Refineries, and Petroleum | Phuc Minh

17/09/2025

Phuc Minh Engineering – Trusted supplier of industrial valves for chemical plants, oil refineries, and petroleum systems. Genuine products with CO-CQ, competitive prices.

Applications of Industrial Valves in Steam and Boiler Systems

17/09/2025

The role of industrial valves in steam and boiler systems In factories using steam and boiler systems, safety control and energy efficiency are critical. Industrial valves play a vital role in:

Industrial Valves – Effective Flow Control Solutions | Phuc Minh Engineering Co., Ltd.

17/09/2025

What is an industrial valve? Industrial valves are essential mechanical devices in piping systems, responsible for regulating, opening/closing, and controlling the flow and pressure of liquids, gases, or steam. They are widely applied in many industries:

Composite Hose – Leading Anti-Corrosion, Chemical-Resistant Flexible Hose Solution in Vietnam

11/08/2025

High-quality imported composite hose, resistant to corrosion, chemicals, oils, and solvents. Available in Vietnam at competitive prices, full size range, and fast delivery.

Comprehensive Valve and Process Control Solutions for Key Industries

16/07/2025

Water Treatment Industry – Scale and Challenges Water treatment is a vital sector, ensuring safe water supply for both residential and industrial use. As urbanization and industrialization accelerate, water treatment systems must meet increasingly stringent requirements: Ensure output water quality meets national and international standards. Maintain continuous, stable operation while minimizing unexpected downtime. Optimize energy efficiency and reduce operational and maintenance costs. Integrate monitoring and automation for enhanced remote control and management. Comply with strict environmental protection regulations and carbon emission reduction goals.

.png)